New Project to Install Biodigesters and Update on Sustainability

As the college continues to work on sustaining the carbon neutrality it accomplished in 2020, “our intent is to continue to be carbon neutral and we will again have zero net emissions for fiscal year 2021,” said Neil Leary, director of the Center for Sustainability Education and one of three livestock and energy projects managers at Dickinson’s farm.

Ken Shultes, another manager at Dickinson’s Farm, says that carbon neutrality is a goal that “requires continued vigilance and nurturance over time in order to maintain and improve upon,” and that the school is “making big efforts in FY21 to ensure that we are reducing energy in vacant or reduced occupancy buildings, while the campus is in remote or partially remote mode.”

He indicated that already during the first 6 months of 2021’s fiscal year, the college’s efforts to reduce energy have culminated in a reduction of “overall electricity and natural gas consumption by more than 25%, and associated emissions,” said Shultes.

There is also a project underway at the Dickinson Farm, supported by the Center for Sustainability, to finish constructing biodigesters.

“We hope to complete construction in 2022,” said Matt Steiman, a livestock and energy projects manager at the college farm.

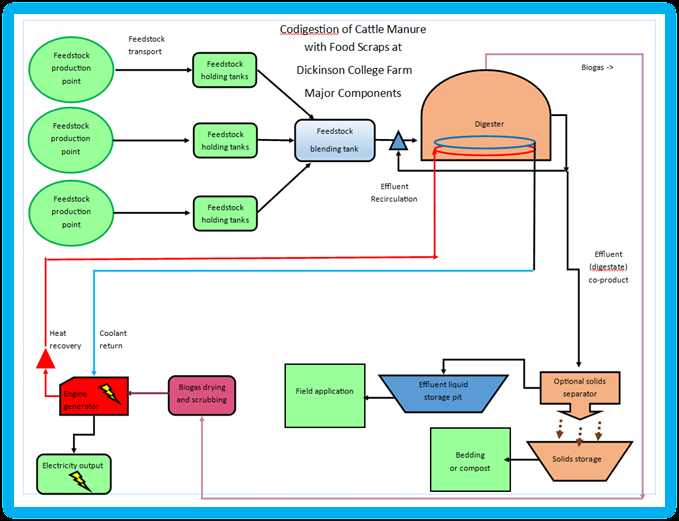

A biodigester converts biodegradable waste into renewable energy and crop fertilizer, said Steiman. To process these materials, “waste materials (at the farm we use cattle manure, food waste from the cafeteria, and spent brewery grain from Molly Pitcher Brewing Co) are mixed with water and put into a warm, air tight container,” said Steiman.

After this process is finished, microbes in the cattle manure will break down the waste into simple compounds, and because there is no air in the system “one class of microbes in the manure called methanogens generate methane gas, which is burnable as fuel,” said Steiman. Additionally, Steiman pointed out that the other major component of biogas produced by the biodigester is carbon dioxide.

Steiman said that the biogas created through biodigesters can be used as fuel for cooking stoves in the cafeteria, or for engines on campus. According to Steiman, the farm has been using a pilot plant since 2016, but there was excess fuel leftover from cooking fuel which led to “exploring the possibilities of converting our extra gas into electricity.”

Due to the amount of energy the farm needed to convert biogas to electricity, the farm partnered up with Triple L Farm, and will “process the manure of their 150 cows as well as everything from Dickinson,” said Steiman.

According to Steiman, the sustainability benefits caused from the biodigesters are “threethold,” by “generating about 200,000 kWh per year of climate-neutral energy from waste products, reducing air pollution and landfill loading, and reducing water pollution from manure runoff at the farm.” Additionally, this project meets goals given by the US EPA and the Pennsylvania Department of Env. Protection, by “increasing food waste diversion from landfills to other beneficial uses,” said Steiman.

The project is also supported by the Natural Resource Conservation Service. The biogas project secured over $800,000 in 2020. Steiman also said that the farm is currently fundraising the plan to meet their goal of finishing in 2022.